Guidance for Using an On-line Chlorine Analyzer for Compliance Monitoring

Section

- Abbreviations

- 1. Does New York State accept on-line chlorine analyzers?

- 2. What is EPA Method 334.0?

- 3. What are ELAP Approved Methods for residual chlorine analyses of grab samples?

- 4. What are benefits of continuous on-line chlorine monitoring?

- 5. What are conditions of approval?

- 6. What are required QC procedures?

- 7. What should I do when QC criteria do not meet requirements?

- 8. What are the record keeping requirements?

- 9. What are the alarm requirements?

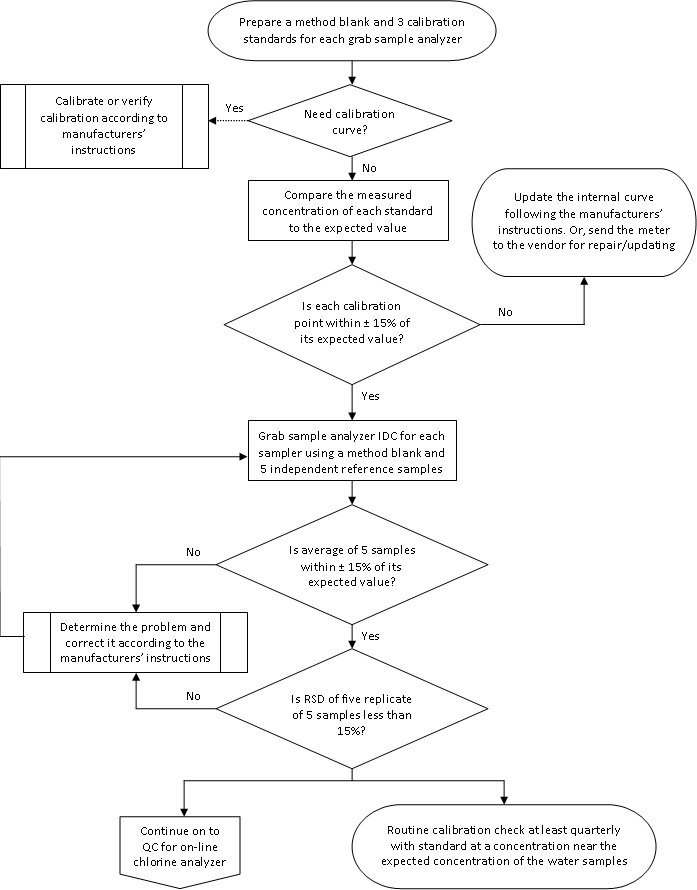

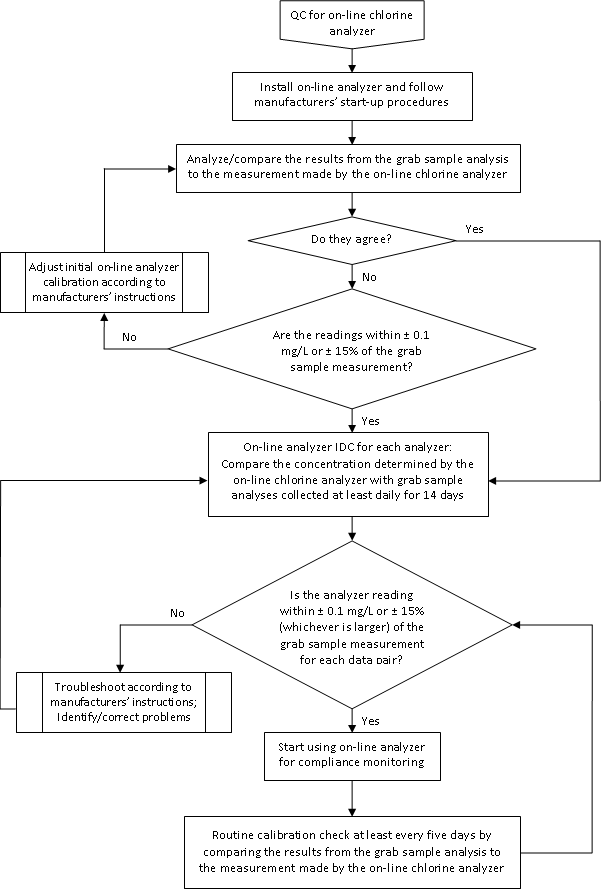

- Flowchart : QC Requirement When Grab Sample Analyses Are Performed In Conjunction With On-Line Chlorine Analyzers.

Abbreviations

- ELAP – Environmental Laboratory Accreditation Program

- EPA – Environmental Protection Agency

- IDC – Initial Demonstration of Capability

- QC – Quality Control

- PWS – Public Water System

- RSD – Relative Standard Deviation

- SD – Standard Deviation

1. Does New York State accept on-line chlorine analyzers?

New York State Department of Health (NYSDOH) will allow water systems to use on-line chlorine analyzers in accordance with EPA Method 334.0 for compliance monitoring of residual chlorine in drinking water with conditions described in this document.

2. What is EPA Method 334.0?

EPA 334.0 is a performance based method and covers all on-line chlorine analyzers when used in conjunction with a grab sample reference method that is approved by Environmental Laboratory Accreditation Program (ELAP). EPA 334.0 is intended to be used when chlorine residuals are in the range of 0.2 mg/L to 4 mg/L. When residual chlorine results are outside this range, grab samples must be analyzed using approved grab sample methods for compliance purposes. Grab samples must be also analyzed if on-line analyzer readings indicate a large unexpected change in chlorine residual that may indicate problems with monitoring equipment, or on-line monitoring equipment is not functioning properly. Before a grab sample reference method is used to adjust the calibration of or verify measurements by the on-line chlorine analyzers, its accuracy must be confirmed first. The full description for EPA Method 334.0 can be found at www.epa.gov/safewater/methods/pdfs/methods/met334_0.pdf

3. What are ELAP Approved Methods for residual chlorine analyses of grab samples?

| Analyte | Technology | Method Description | ELAP Method No. |

|---|---|---|---|

| Free Residual Chlorine | Amperometric Amperometric Amperometric Colorimetric Colorimetric Titrimetric | ASTM D1253-86,96,03,08 SM 18-21 4500-Cl D (00) ChloroSense SM 18-21 4500-Cl H (00) SM 18-21 4500-Cl G (00) SM 18-21 4500-Cl F (00) | 1080 1073 1206 1162 1078 1077 |

| Total Residual Chlorine | Amperometric Amperometric Amperometric Amperometric Colorimetric Potentiometric Titrimetric | SM 18-21 4500-Cl E (00) ChloroSense ASTM D1253-86, 96, 03, 08 SM 18-21 4500-Cl D (00) SM 18-21 4500-Cl G (00) SM 18-21 4500-Cl I (00) SM 18-21 4500-Cl F (00) | 1074 1206 1080 1073 1078 1161 1077 |

4. What are benefits of continuous on-line chlorine monitoring?

Continuous monitoring of water quality can provide operational advantages and improve public health protection. This provides real time information that can improve an operator's ability to control water treatment processes such as disinfection and turbidity removal. Continuous monitoring is a requirement of the State Sanitary code for some water quality indicators, depending on the source water, treatment type, and population served. For residual chlorine, continuous monitoring is required for public water systems (PWS) that serve more than 3,300 people and that use surface water or groundwater under the direct influence of surface water. Continuous chlorine monitoring is also required for PWS serving over 3,300 people with groundwater sources when required to perform 4-log treatment. In addition to improved operations and public protections, automated continuous monitoring devices can relieve operators from the burden of frequent sampling and manual data recording.

5. What are conditions of approval?

Pursuant to 5-1.71(b) and 5-1.72(a) of State Sanitary Code, quality control (QC) criteria must be met in order to use an on-line chlorine analyzer for compliance chlorine monitoring. The same QC procedures are recommended but not required for on-line analyzers that are not used for compliance monitoring.

Both initial and routine QC need to be performed to meet the conditions of approval. Initial QC includes: 1) grab sample method calibration; 2) initial demonstration of capability (IDC) by each sampler to verify the accuracy and precision of grab sample; 3) on-line chlorine analyzer calibration; 4) IDC to verify the accuracy of on-line analyzer results for 14 consecutive days. Routine QC includes a quarterly calibration check for grab sample method and every five day comparison of on-line results with grab sample results. The grab sample analyzer used to verify on-line analyzer accuracy must use a method that is approved for drinking water compliance monitoring. The accuracy and precision of the grab sample and the on-line chlorine analyzer must be periodically verified in accordance with this document (and adjustments made when necessary) based on results from grab sample analyses (refer to item No.6 and a flowchart).

6. What are required QC procedures?

| Grab Sample | On-line Chlorine Analyzer | |

|---|---|---|

| Initial | 1. Verify internal calibration curve according to the manufacturer's instructions, or prepare calibration curve using a method blank(1) and a set of at least three aqueous calibration standards. The standards must span the concentration range that is expected to be observed in the grab samples with the minimum at 0.2 mg/L. Each calibration point must be within ± 15% of its expected value. 2. Each field sampler must perform an IDC by analyzing a method blank(1) and five replicate independent reference samples at the same concentration. The concentration of the samples should be in the mid range of the calibration curve or near the expected concentration of the water samples. The average concentration for the five replicates must be within ± 15% of the expected value to demonstrate accuracy. The relative standard deviation (RSD)(2) must be ± 15% to demonstrate precision. | 1. Install the analyzer according to the manufacturer's specifications. 2. After the accuracy of the grab sample measurement is verified, collect and analyze a grab sample collected as close as feasible to the location where the sample enters the on-line chlorine analyzer. Compare the results from the grab sample analysis to the measurement made by the on-line chlorine analyzer. Adjust analyzer to have analyzer readings agree with grab sample measurements within 0.1 mg/L or ± 15%. 3. Perform the IDC for the each on-line chlorine analyzer(3) by comparing on-line chlorine analyzer readings with grab sample analyses collected at least daily for consecutive 14 days. The analyzer reading must be within ± 0.1 mg/L or ± 15% (whichever is larger) of the grab sample measurement for each data pair. When multiple on-line chlorine analyzers are being installed, the IDC may be shortened if the same model analyzer is installed at each location and the water quality characteristics and treatment processes are equivalent at each location. |

| Routine | Prepare an aqueous calibration check standard at a concentration near the expected concentration of the water samples. The grab sample measured concentration of the calibration check standard must be within ± 15% of the expected value. The results from analyses of calibration check standards must be recorded and maintained according to item 8 of this document. Min. calibration check frequency: quarterly. | 1. Compare on-line chlorine analyzer readings with grab sample analyses. The analyzer reading must be within ± 0.1 mg/L or ± 15% (whichever is larger) of the grab sample measurement for each data pair. 2. Adjust the calibration of the analyzer so it gives the same value as the grab sample analysis. Follow the manufacturer's instructions. 3. After a major repair or after replacement of the on-line chlorine analyzer with an equivalent model, perform the initial calibration procedure. Return to the routine schedule for grab sample comparisons after verifying the accuracy of the analyzer on a daily basis for 7 consecutive days (or business days). Minimum calibration check frequency: every five days. |

(1)The method blank concentration must be ≤ ⅓ the concentration of the lowest standard used to prepare/verify the calibration curve.

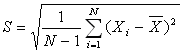

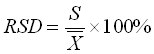

(2)The standard deviation and RSD are calculated using the equation  and

and  , respectively, where S is the standard deviation for the replicate values,

, respectively, where S is the standard deviation for the replicate values,  is the average value for the replicates, N is the number of replicates, Xi is the individual observation result.

is the average value for the replicates, N is the number of replicates, Xi is the individual observation result.

(3)The IDC is not required if historical operating data for the on-line chlorine analyzer demonstrate the criterion are being met on an on-going basis. Historical data must show that the analyzer remains in agreement with the grab sample method over a period of two consecutive weeks without analyzer maintenance or calibration adjustment.

7. What should I do when QC criteria do not meet requirements?

Acceptable QC described in this document is an essential condition of approval for the use of on-line chlorine analyzers. Therefore, if QC fails, the on-line chlorine analyzer can not be used for compliance monitoring of residual chlorine, and grab samples must be collected and analyzed as soon as possible until problems are identified and resolved.

8. What are the record keeping requirements?

QC results do not need to be submitted but must be recorded and kept available for inspection by the Local Health Department (LHD) during a sanitary survey or when otherwise requested by the State or LHD. The results must be kept for five years.

9. What are the alarm requirements?

It is critical that on-line analyzers used to monitor chlorine residual have an effective alarm system to alert operators to critical conditions, including: low chlorine residual (less than 0.2 mg/L); high chlorine residual (above the maximum residual disinfectant level of 4 mg/L); and equipment problems. On-line chlorine analyzers at locations that are not continuously manned are expected to have call out features enabled.

For pre-existing on-line chlorine analyzers that do not have the capacity to provide all alarm functions, priority should be given to activating low and high chlorine residual alarms and remote call out features. Alarms for monitoring equipment problems can be replaced by manual, daily checks to ensure continued proper operation of the monitoring equipment.

Flowchart : QC Requirement When Grab Sample Analyses Are Performed In Conjunction With On-Line Chlorine Analyzers.